Inventory Management

-

Sales Management & Invoicing

9769 Views . -

Getting Started

9448 Views . -

Customer Relation Management - CRM

8713 Views . -

adhoc Education Datasheet

7216 Views . -

Purchase Management

6057 Views . -

Users-Management

5463 Views . -

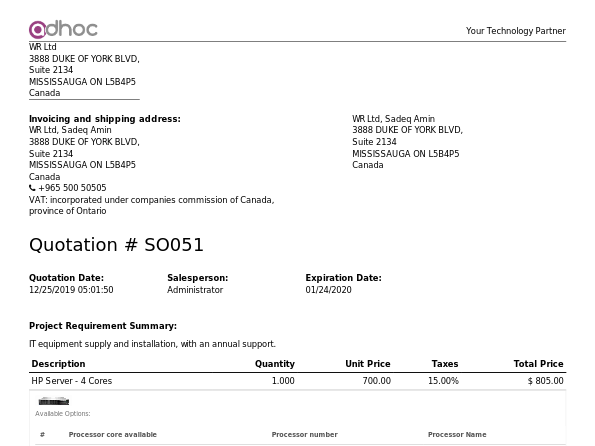

sample-quote customized

3716 Views . -

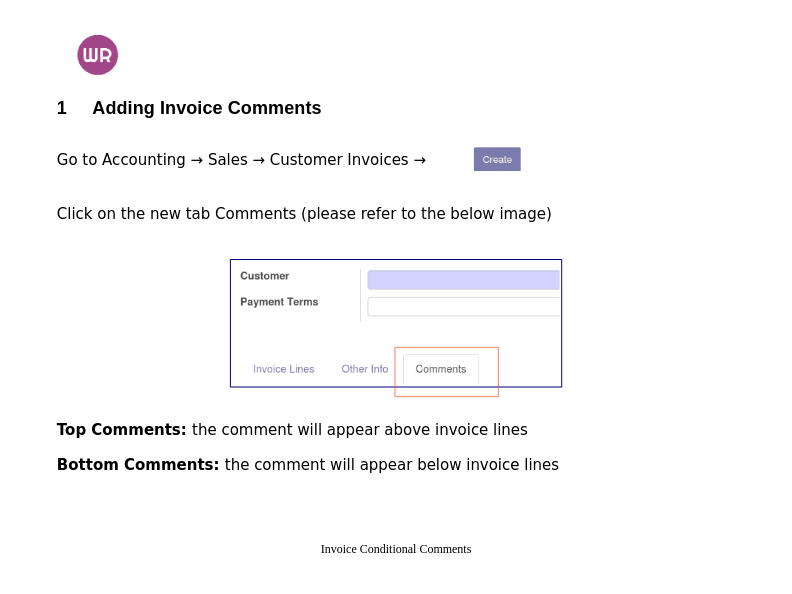

Invoice Conditional Comments

2794 Views . -

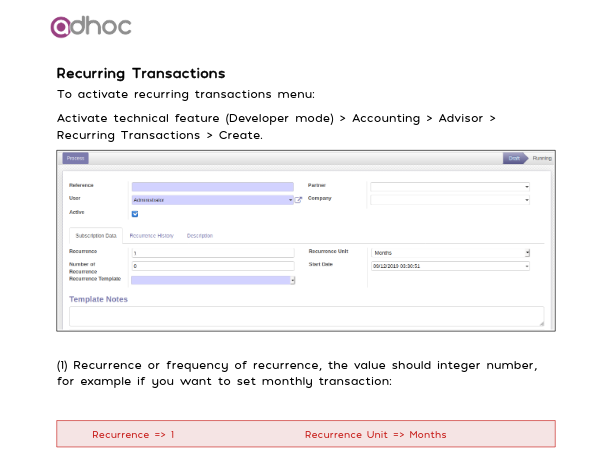

Recurring Transactions

2369 Views . -

Project Costing

1583 Views . -

Inventory Terminologies

1570 Views .